Navigating the Nylon Niche: A Noteworthy Narrative on Diverse 3D Printing Filaments

- Owen Krumm

- Aug 11, 2023

- 2 min read

Updated: Aug 13, 2023

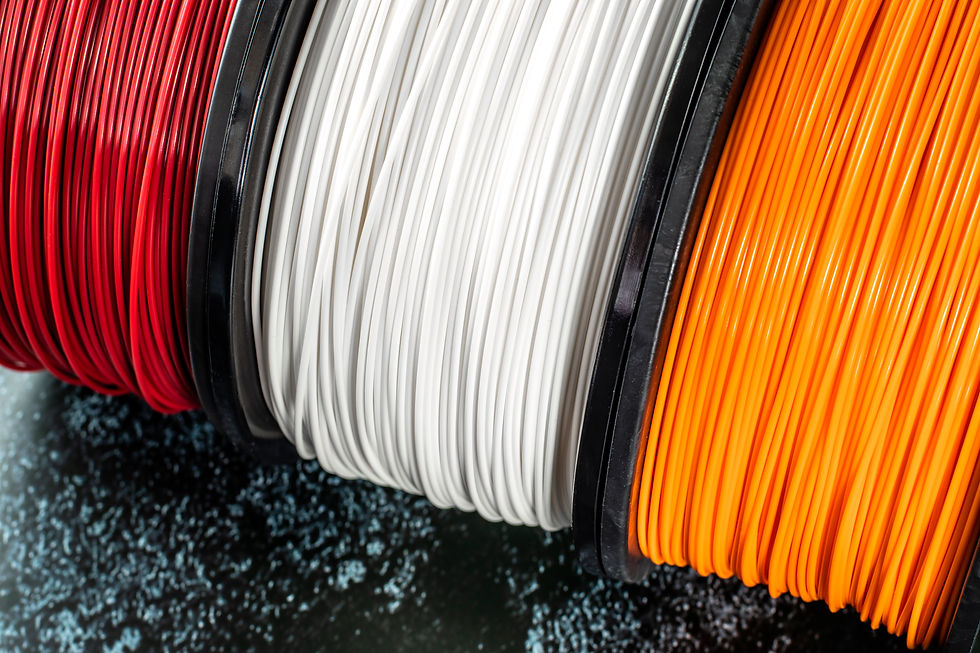

Unveiling the Wonders of Nylon Filaments

Nylon, a synthetic polymer renowned for its durability and flexibility, has seamlessly integrated into the world of 3D printing. Nylon filaments are celebrated for their superior layer adhesion, impact resistance, and mechanical resilience. These characteristics make nylon a preferred choice for crafting functional prototypes, intricate designs, and sturdy end-use components.

Nylon 6 (PA 6): The Versatile Vanguard

Derived from caprolactam, Nylon 6 boasts a balanced blend of properties, including remarkable toughness, chemical resistance, and low friction. Its versatility renders it suitable for a plethora of applications, spanning mechanical components to everyday consumer goods.

Nylon 12 (PA 12): The Engineering Marvel

Nylon 12 shines with its exceptional impact strength and heat resistance, making it a staple for engineering-grade parts. With its capacity to endure challenging environments and maintain dimensional stability, Nylon 12 emerges as an ideal choice for aerospace, automotive, and industrial applications.

Glass-Filled Nylon: Elevating Strength and Sturdiness

The synergy between nylon and glass fibers results in specialized filaments that offer elevated strength-to-weight ratios, heightened stiffness, and enhanced dimensional stability. These attributes make them indispensable for applications requiring uncompromising structural integrity.

Nylon Carbon Fiber Composites: Fusing Innovation and Resilience

Pairing nylon with carbon fibers yields filaments that combine the benefits of both materials. These filaments showcase amplified strength and stiffness, catering to scenarios where robustness is paramount—whether for aerospace components or sports equipment.

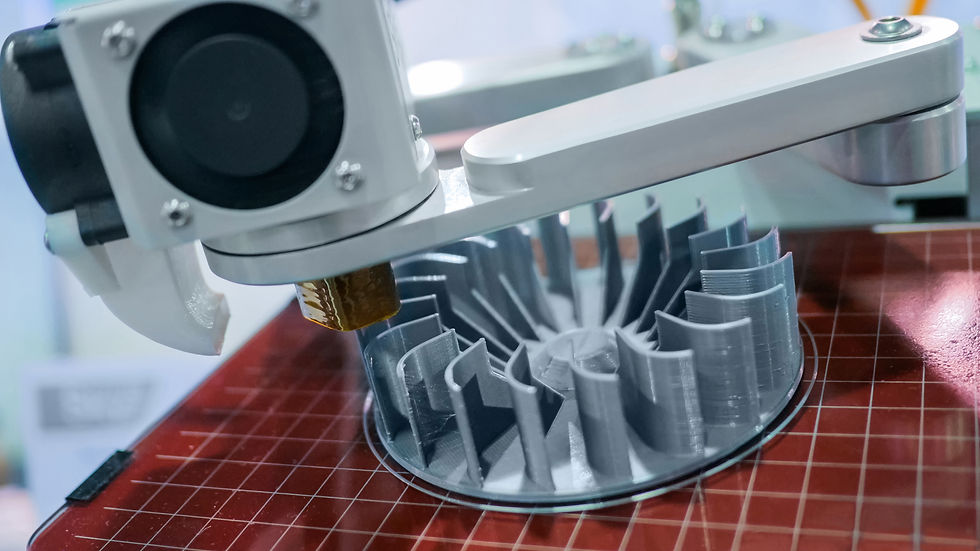

Optimizing Your Nylon Printing Experience

Crafting successful prints with nylon filaments mandates a strategic approach, considering factors like mechanical prerequisites, usage contexts, and post-processing requisites. A harmonious balance between attributes such as layer adhesion, printability, and dimensional precision is pivotal for achieving desired outcomes.

Key Printing Insights

Enforce Bed Adhesion: Taming nylon's warping propensity calls for a heated bed and judicious application of bed adhesives or tapes to ensure optimal adhesion.

Temperature Precision: Nylon filaments necessitate higher extrusion temperatures than conventional materials. Meticulous temperature adjustments wield a profound influence on print quality.

Moisture Management: Nylon's hygroscopic nature demands pre-print drying to stave off defects triggered by moisture entrapment.

Glass-Filled Nylon Considerations: Prints employing glass-filled nylon may necessitate heightened nozzle wear awareness due to the abrasive nature of glass fibers, this can be avoided with the use of hardened steel nozzles.

Still got questions?

Contact us with your filament questions through our contact form or shoot us an email!

Comments